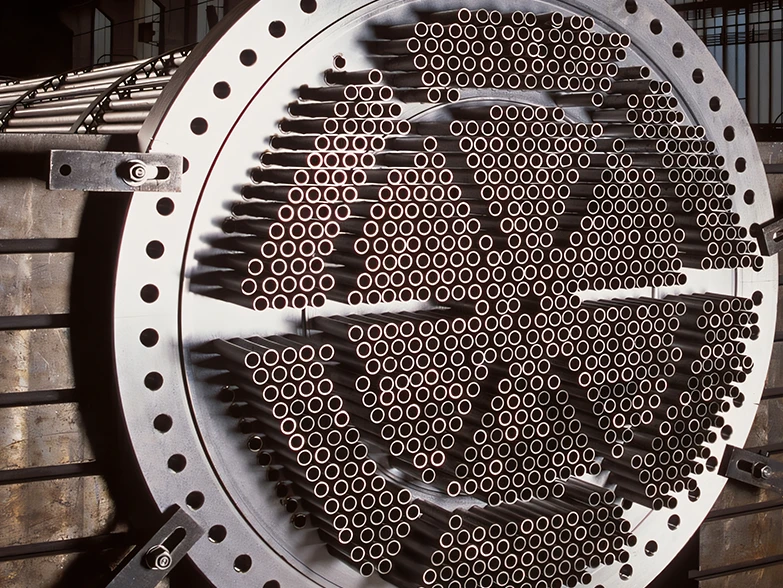

We manufacture economizers with built-in multi-pass spiral tube heat exchangers, with a bottom common tube collector for waste heat recovery according to standards and customer requirements. The economizer consists of tube bundles through which the heated medium flows. Materials are selected according to the environment and medium requirements. The economizer is flange-divided and installed on legs or brackets in front of the heater. The outer surface is usually painted, but galvanizing, pickling, and passivation for austenitic steels can also be provided. The delivery includes complete documentation with all required certificates and tests.

Carbon steels (P265GH,P235GH, P245GH, P280GH, P355NL1/NH, P275NL1, S235JR, S355JR)

Austenitic stainless steels (1.4301, 1.4307, 1.4404, 1.4435, 1.4539, 1.4541, 1.4571, 1.4828, 1.4845)